To get the most out of pre-competitive basic research, it makes sense to bundle various competences. Looking for matching partners is most fruitful on an international basis. But the effort for small and medium-sized enterprises (SMEs) to put up such cooperation is quite complex and time-consuming. To support that networking the European Union set up the international funding initiative CORNET (Collective Research Networking) in 2005. Since then more than 270 projects with more than 4.500 SMEs were realised. It is mostly European countries participating, but also some countries from overseas such as Brazil, Japan or Canada. Because SMEs very often do not have their own research department CORNET is also a funding program. The cooperation partners of those joint research projects get their money by their national funding agencies - in the case of Germany this would be the Federal Ministry of Economics and Energy that also funds the Industrial Basic Research (IGF), in Austria, it is the Research Promotion Agency (FFG).

Photo by Calvin Hanson on Unsplash

Joint research for more innovation

To ensure that as many enterprises as possible benefit from the funding, it is essential that in every project there are at least five SMEs from each partnering country participating. And the application is worth it. More than 66 per cent of the inquiries are granted. In Germany, only research associations organised in the German Federation of Industrial Research Associations (AiF) are allowed to apply. The Textile Research Association (FKT) provides advice and support for companies that are interested in participating in the CORNET-program.

Research to improve textile recycling

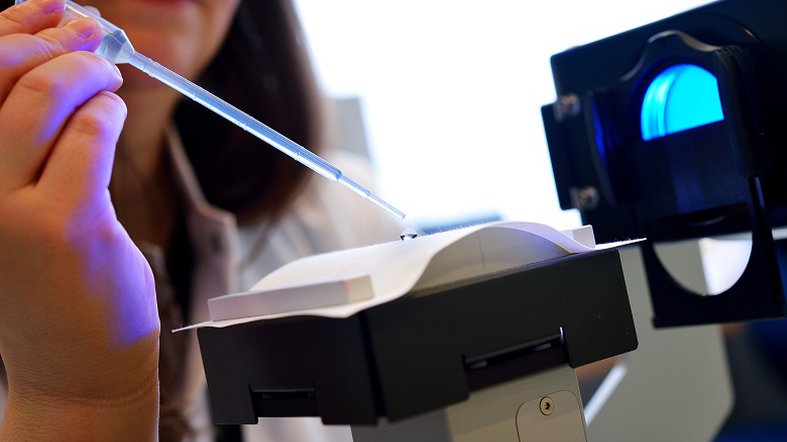

German textile companies seem to be very engaged in being part of joint basic research projects on an international basis: Since 2010 the FKT applied for 36 CORNET-projects successfully. One of those is the project MARKER, in which next to various enterprises the Institute for Textile Technology and the Institute for Processing and Recycling of the RWTH Aachen took part as well. The focus of the research activities of MARKER lay on optimising textile recycling by labelling textiles and textile fibres with uv-markers. Those markers are integrated into the filament directly when producing it in a melt-spinning process or by coating the finished textile.

Different concentrations and several combinations of markers had been looked at, which fluoresce in different colours. The project’s results are supposed to contribute to better tracking of the textile product during its life cycle, to simplify the recognition of materials that were used to produce the product and to achieve higher recycling rates by sorting the textile waste much more efficiently.

Safety workwear on a new level

The sensible parts of safety workwear are quite inflexible. That makes the clothing relatively uncomfortable. To improve that, the CORNET-project RAPACOAT was initiated. Newly textile structures with a functional 3D-coating were developed in the project with the Saxon Textile Research Institute being part of the team. That soft and flexible coating is based on ceramic printing pastes. It is applied by screen-printing. The resulting textile structures are air-permeable and breathable. Additionally, their stitch and abrasion resistance and the protection against cuts are excellent. For example, the protection against needle stitches and cuts caused by sharp edges is improved significantly by the coating. At the same time, the combination of the used materials offers more flexibility, improved wearing comfort and an optimised tactile sense for the wearer.

Textile measuring humidity

The range of topics of CORNET-funded projects is very diverse. One of them, AMBITEX for example, in which the Niederrhein University played a significant role, had medical textiles in focus. The textiles worked at are able to measure moisture – for example, to watch over bed-ridden patients. Sweat and body heat can lead to skin irritation or in the worst case to pressure sores.

Not only in the health sector, but also in the construction industry the monitoring of humidity is an important factor. That is especially the case when it comes to insulation material for low energy buildings because even the most intelligent ventilation system is not able to prevent humidity between the isolation layers. The occurrence of mould and microorganisms might be the result. AMBITEX has addressed both fields of application simultaneously.

In the project, textile sensors were developed, that are able to reliably determine the relative air humidity and dew points. They are built similar to a capacitor and also work that way. The electrical capacitance, which depends on the water content of the textile sensor, can be used to electrically measure the level of moisture. No special machinery or other equipment is needed to produce the sensors, so it can therefore be managed quite easily in textile enterprises.

All of those three projects are examples for CORNET supporting SMEs to widen their product range in an interesting way. They are able to develop new markets in cooperation with research institutes.

Get to know more about CORNET.

Finden Sie hier weitere interessante Inhalte